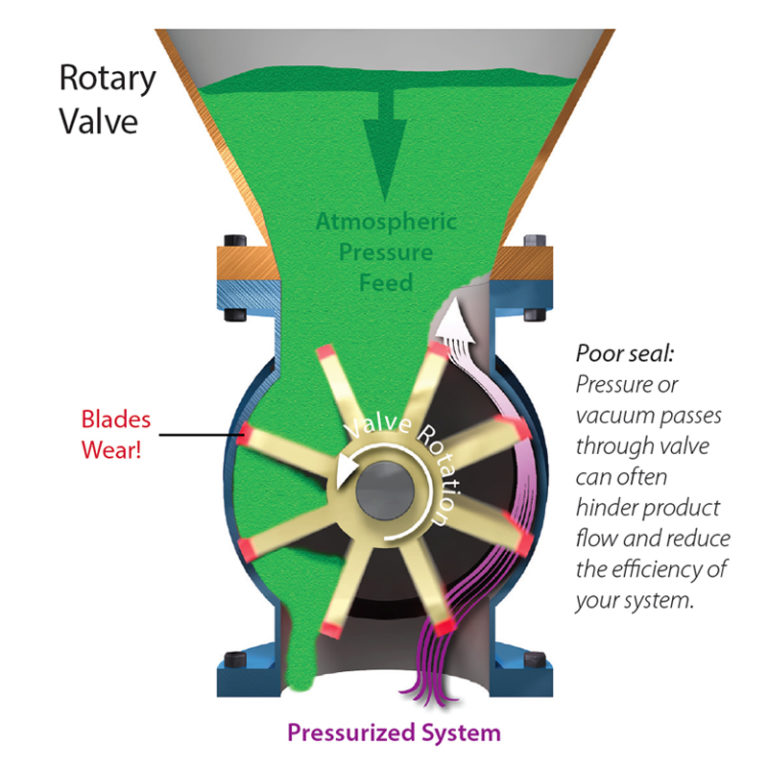

ROTARY AIRLOCK VALVES.

WHY TO CHOOSE?

KEY BENEFITS.

PRECISION MACHINING

Accurate machining to close tolerances and fit, on rigid and accurate machine tools, where internal clearances down to a minimum consistent with satisfactory operation of the Rotary Valves. We have designed and perfected special tools to assure thah the valve's end plates , housing, and rotor are precision-machined. We do all the machining operations in our own shop to maintain accuracy. No machining operations are subcontracted out.

DRIVES

A number of options are available for driving the rotors. The either worm-gear driven or chain-sprocket driven depending upon the material to be conveyed and granule size. Either option is available for obtining a RPM in the range of 20-60 RPM. DC drvien motors are nomally used but we can also offer 220volts single phase motor as well.

Rotors are made integral by welding the heavy section vanes onto the steel shaft Stress relieving and then machined.

The use of steel rather than cast iron for the rotors prevents vanes from breaking off when a foreign object become lodged between the rotor and housing while in the locking cycle. With a steel rotor, the motor will simply stall. The overload heaters in the motorstarter will cause the motor starter to drop out, disconnecting the power to the motor.

The rotary valves we manufacture have large diameter shafts for minimum deflection under load. Bearings are housed outboard of the end plates; they are kept clean and free of foreign matter by their own seals. The bearings are over-sized with respect to the load they are subjected to and are manufactured out of sintered, non-ferrous materials and they are factory lubricated for the lift of the bearings. This material is designed to give maximum life when operating un-lubricated.